A vacuum drying plant is a specialized facility designed to remove moisture from various materials using a vacuum system. This process is widely used in industries such as food processing, pharmaceuticals, chemicals, and precision manufacturing.

The vacuum drying plant is typically housed in a dedicated building or part of an existing facility. The design should consider factors such as space requirements, airflow, utility connections, and safety regulations.

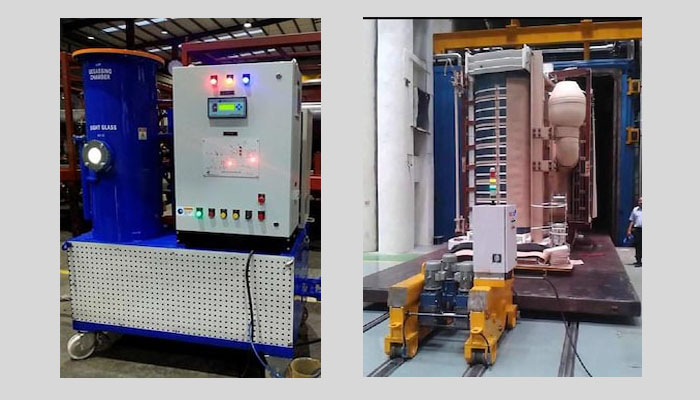

The heart of the vacuum drying plant is the vacuum system. It consists of a vacuum pump, vacuum chambers, filtration units, and control systems. The vacuum pump creates a low-pressure environment inside the chambers, aiding the removal of moisture.

Depending on the nature of the materials to be dried, various handling equipment may be required. This may include conveyors, elevators, or automated systems to transfer materials to and from the drying chambers.

A Vacuum drying plant may require additional equipment such as heaters or coolers to control the temperature inside the chambers. Filtration units, such as cyclones or baghouses, are also installed to separate dust and other particles from the process air.

Before starting the vacuum drying process, the materials are prepared accordingly. This may involve crushing, grinding, or mixing to ensure proper and uniform drying.

The prepared materials are loaded into the vacuum chamber using the material handling equipment. Care is taken to ensure the chambers are not overloaded, allowing for proper airflow.

The vacuum pump is activated, creating a reduced pressure environment inside the chambers. This lowers the boiling point of water, facilitating its evaporation and removal.

The drying cycle is controlled based on the specific needs of the materials being processed. It involves maintaining the desired temperature, pressure, and time parameters to ensure effective drying. The moisture evaporates as steam and is removed from the chamber by the vacuum pump.

The evaporated moisture is collected and separated from the process air using the filtration units. This prevents it from re-entering the drying chambers and ensures a continuous drying process.

Once the drying cycle is complete, the dried materials are unloaded from the chambers using the material handling equipment. They are then transported for further processing, packaging, or storage.

To maintain the efficiency and quality of drying, regular cleaning and maintenance of the vacuum chambers are necessary. This helps to prevent contamination and maintain optimal drying conditions.

Throughout the drying process, quality control measures are implemented to ensure that the materials meet the desired specifications. This may involve periodic sampling, testing, and analysis of the dried materials.

The setup and process of a vacuum drying plant are crucial for efficiently removing moisture from various materials. Proper design, equipment selection, and operational controls play a significant role in achieving effective drying results and ensuring product quality.