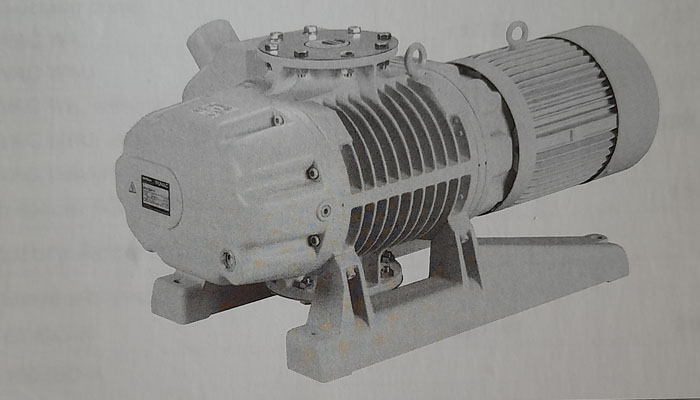

The Roots vacuum pump is a powerful and widely-used device in various industries, known for its ability to efficiently remove gases and create a vacuum. This write-up will dive into the key features, working principles, and wide-ranging applications of Roots vacuum pumps.

1. Robust Design: Roots vacuum pumps are designed to handle demanding conditions and operate reliably under high temperatures and extreme pressures. They feature sturdy construction with precision-machined rotors for enhanced durability.

2. High Pumping Speed: These pumps are known for their high pumping speed, allowing them to quickly remove gases and create a vacuum in a relatively short amount of time.

3. Oil-Free Operation: One of the major advantages of Roots vacuum pumps is their oil-free operation. They do not require lubricating oil, eliminating the risk of contamination and reducing maintenance costs.

Roots vacuum pumps operate on the principle of positive displacement. They consist of two interlocking, close-clearance rotors known as "Roots" rotors or lobes. When the rotors rotate, they create voids that trap and move gas from the inlet to the exhaust. These rotors work without contacting each other or the pump housing, ensuring minimal wear and tear.

The operation of a Roots vacuum pump is complemented by the presence of a backing pump or secondary pump. The backing pump helps in maintaining a vacuum by removing the gas exhausted by the Roots pump.

1. Industrial Processes: Roots vacuum pumps find extensive usage in various industrial processes, such as vacuum distillation, drying, degassing, and freeze drying. Their high pumping speed and reliability make them invaluable in industrial applications, ranging from chemical and pharmaceutical to food processing and packaging.

2. Semiconductor Manufacturing: In the semiconductor industry, Roots vacuum pumps play a vital role in creating and maintaining the required vacuum levels during processes like thin film deposition, plasma etching, and lithography.

3. Research and Development: Roots vacuum pumps are widely used in research laboratories and institutions for creating and maintaining vacuum environments. They are used in experiments, analytical instruments, and vacuum coating systems.

4. Environmental Applications: Roots vacuum pumps are employed in environmental applications, including wastewater treatment and landfill gas extraction. They help in creating a vacuum for efficient filtration and removal of gases.

1. Enhanced Efficiency: Roots vacuum pumps offer high pumping speeds, enabling faster evacuation and reducing process cycle times. Their oil-free operation eliminates the need for oil changes, resulting in reduced downtime and maintenance costs.

2. Reliability: With their robust construction and minimal wear and tear, Roots vacuum pumps provide long-lasting reliability and consistent performance. They can handle both low and high vacuum pressure demands efficiently.

3. Contamination-Free Operation: As they do not require lubricating oil, Roots vacuum pumps eliminate the risk of oil contamination, making them suitable for sensitive applications where purity is crucial.

Roots vacuum pumps have become indispensable in various industrial processes and scientific research due to their efficient gas removal capabilities and reliable operation. Their sturdy design, oil-free operation, and high pumping speeds make them ideal for a wide range of applications. Whether in the semiconductor industry, environmental applications, or research laboratories, the Roots vacuum pump continues to be a trusted and valuable tool for creating and maintaining a vacuum.